ထုတ်ကုန်များ

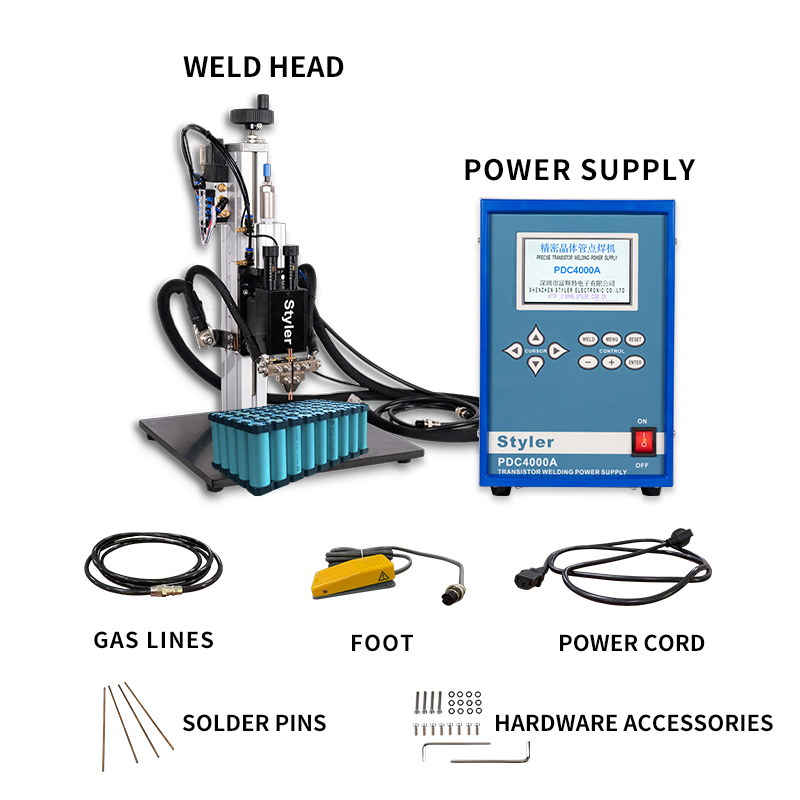

PDC2000A ဂဟေဆော်စက်

ထုတ်ကုန်အင်္ဂါရပ်များ

ဂဟေလုပ်ငန်းစဉ်၏ ကွဲပြားမှုကို သေချာစေရန်အတွက် ပဏာမ စဉ်ဆက်မပြတ်လျှပ်စီးကြောင်း၊ အဆက်မပြတ်ဗို့အားနှင့် ဟိုက်ဘရစ်ထိန်းချုပ်မှုမုဒ်ကို လက်ခံကျင့်သုံးပါသည်။

ကြီးမားသော LCD ဖန်သားပြင်သည် ဂဟေဆော်နေသောလျှပ်စီးကြောင်း၊ လျှပ်ကူးပစ္စည်းကြားရှိ ပါဝါနှင့် ဗို့အားအပြင် ထိတွေ့မှုကို ခံနိုင်ရည်ရှိကြောင်း ပြသနိုင်သည်။

Built-in detection function- တရားဝင် power-on မဖွင့်မီ၊ workpiece ၏ပါဝင်မှုနှင့် workpiece ၏အခြေအနေတို့ကိုအတည်ပြုရန် detection current ကိုသုံးနိုင်သည်။

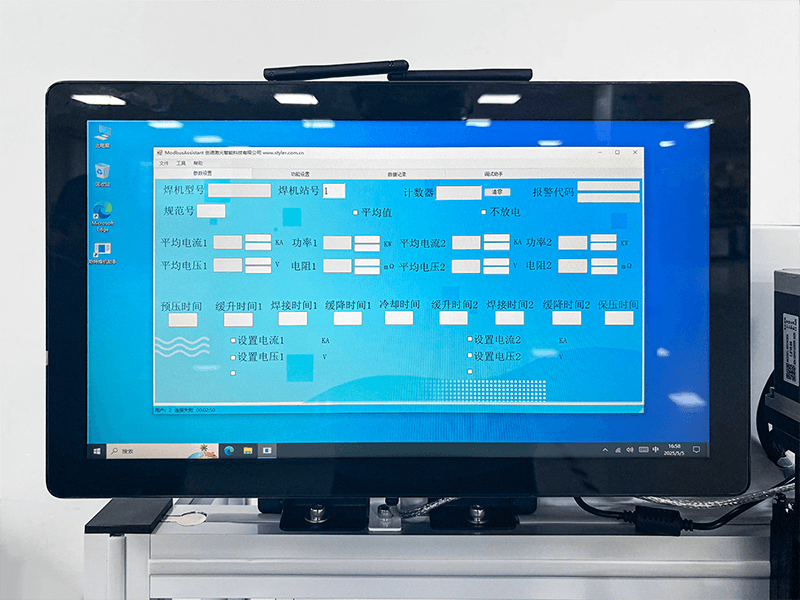

အမှန်တကယ် welding parameters တွေကို RS-485 serial port မှတဆင့် output လုပ်နိုင်ပါတယ်။

ပြင်ပ port များမှတဆင့် စွမ်းအင်အုပ်စု ၃၂ ခုကို နိုင်ထက်စီးနင်း ပြောင်းလဲနိုင်သည်။

ပြီးပြည့်စုံသော input နှင့် output အချက်ပြမှုများ၊

Modbus RTU protocol မှတဆင့် parameter များကိုအဝေးမှမွမ်းမံခြင်းနှင့်ခေါ်ဆိုနိုင်သည်။

ထုတ်ကုန်အသေးစိတ်

ကန့်သတ်အရည်အချင်း

| စက်ပစ္စည်း ကန့်သတ်ချက်များ | |||||

| မော်ဒယ် | PDC10000A | PDC6000A | PDC4000A | ||

| MAX CURR | 10000A | 6000A | 2000A | ||

| MAX POWER | 800W | 500W | 300W | ||

| အမျိုးအစား | STD | STD | STD | ||

| MAX VOLT | 30V | ||||

| ထည့်သွင်းခြင်း။ | single phase 100~120VAC သို့မဟုတ် single phase200~240VAC 50/60Hz | ||||

| ထိန်းချုပ်မှုများ | 1 .const , curr ;2 .const , volt ;3 .const . curr နှင့် volt ပေါင်းစပ်မှု;4 .const power;5 .const .curr နှင့် power ပေါင်းစပ်မှု | ||||

| TIME | ဖိအားအဆက်အသွယ်အချိန်: 0000 ~ 2999ms ခံနိုင်ရည်ကြို-ထောက်လှမ်းဂဟေအချိန်: 0 .00 ~ 1 .00ms ကြိုတင်သိရှိနိုင်ချိန်- 2ms (ပုံသေ) တက်လာချိန်- 0 .00 ~ 20 .0ms ခုခံမှုကြိုတင်ထောက်လှမ်းမှု 1 ၊2 ဂဟေဆက်ချိန်- 0 .00~99 .9ms နှေးကွေးချိန်- 0 .00 ~ 20 .0ms အအေးခံချိန်- 0 .00 ~ 9 .99ms ကိုင်ဆောင်ချိန်- 000 ~ 999ms | ||||

| ဆက်တင်များ

| 0.00~9.99KA | 0.00~6.00KA | 0.00~4.00KA | ||

| 0.00~9.99v | |||||

| 0.00~99.9KW | |||||

| 0.00~9.99KA | |||||

| 0.00~9.99V | |||||

| 0.00~99.9KW | |||||

| 00.0~9.99MΩ | |||||

| CURR RG | 205(W)×310(H)×446(D) | 205(W)×310(H)×446(D) | |||

| VOLT RG | 24KG | 18KG | 16KG | ||

ရွေးချယ်နိုင်သောဆက်စပ်ပစ္စည်းများ

ကွန်ပျူတာ (ဂဟေအဆစ်များကို အချိန်နှင့်တပြေးညီ စောင့်ကြည့်ခြင်း၊ RS485 မှတဆင့် ဒေတာပေးပို့နိုင်သည်)

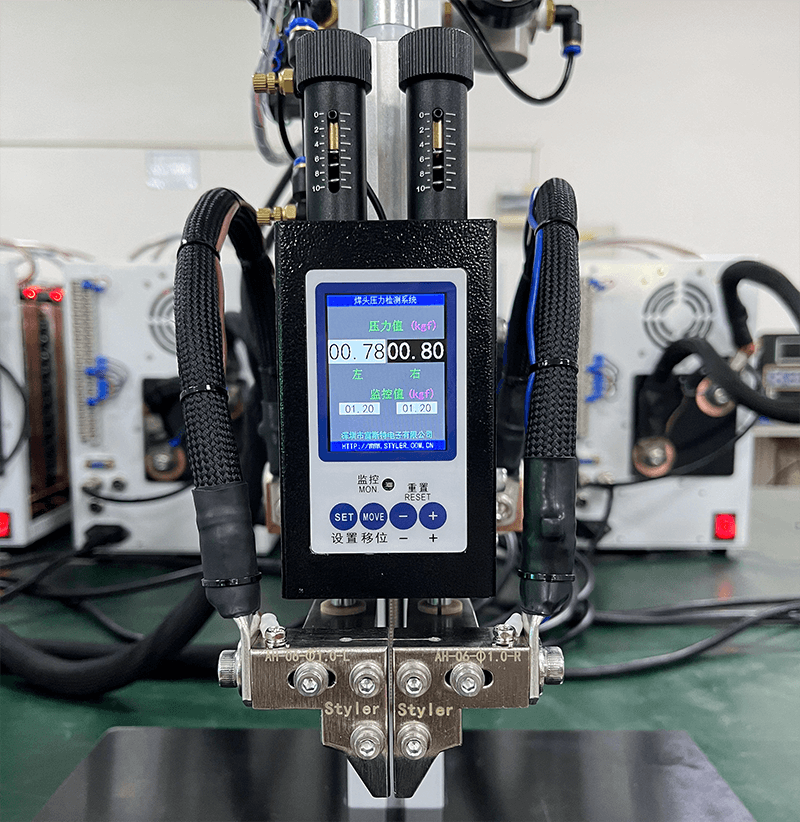

ဂဟေခေါင်းထဲသို့ ဖိအားအာရုံခံကိရိယာတစ်ခု ထည့်ပါ (နှစ်ဖက်လုံးရှိ ကုပ်ကြိုးများ၏ ဖိအားကို တစ်သမတ်တည်းသတ်မှတ်နိုင်ပြီး ဂဟေဆော်နေစဉ်အတွင်း ဖိအားကို စောင့်ကြည့်နိုင်သည်)

သိပ္ပံ ထုတ်ကုန် ဗဟုသုတများ ကျော်ကြားခြင်း။

ကျွန်ုပ်တို့သည် တရုတ်နိုင်ငံ၊ Guangdong တွင် အခြေစိုက်ပြီး 2010 ခုနှစ်မှ စတင်ကာ ပြည်တွင်းစျေးကွက် (50.00%)၊ မြောက်အမေရိက (15.00%)၊ တောင်အမေရိက (5.00%)၊ အရှေ့ဥရောပ (5.00%)၊ အနောက်ဥရောပ (5.00%)၊ အရှေ့တောင်အာရှ (3.00%)၊ အာရှ (3.00%)၊ အရှေ့တောင်အာရှ (3.00%)။ အာရှ(3.00%)၊ အရှေ့အလယ်ပိုင်း(2.00%)၊ အမေရိကအလယ်ပိုင်း(2.00%)၊ မြောက်ဥရောပ(2.00%)၊ ဥရောပတောင်ပိုင်း(2.00%)။ ကျွန်တော်တို့ရုံးမှာ စုစုပေါင်း လူ ၅၁-၁၀၀ လောက်ရှိတယ်။

အစုလိုက်အပြုံလိုက် မထုတ်လုပ်မီ အမြဲတမ်း ထုတ်လုပ်မှုနမူနာ၊ တင်ပို့ခြင်းမပြုမီ အမြဲတမ်းနောက်ဆုံးစစ်ဆေးခြင်း;

Lithium Battery Assembly Automation Line၊Battery Spot Welding Machine၊Battery Sorting Machine၊Battery Comprehensive Tester System၊Battery Aging Cabinet

ကျွန်ုပ်တို့တွင် ခိုင်မာသောနည်းပညာပိုင်းဆိုင်ရာ R&D အဖွဲ့တစ်ခုရှိပြီး လီသီယမ်ဘက်ထရီ တပ်ဆင်ခြင်းနှင့် ထုတ်လုပ်ရေးစက်မှုလုပ်ငန်းတွင် အတွေ့အကြုံကြွယ်ဝသော နှစ်ပေါင်းများစွာ လုပ်ဆောင်နေပါသည်။ ယခုအခါ ကုမ္ပဏီတွင် စက်ယန္တရားများနှင့် စက်ကိရိယာများ၏ မော်ဒယ်အမျိုးမျိုး၊ အမျိုးအစား အမျိုးမျိုးနှင့် မော်ဒယ်များ ရှိသည်။

လက်ခံထားသော ပို့ဆောင်မှုစည်းမျဉ်းများ- FOB၊ EXW; လက်ခံထားသော ငွေပေးချေမှုငွေကြေး-USD၊EUR၊JPY၊CAD၊AUD၊HKD၊GBP၊CNY၊CHF၊ လက်ခံထားသော ငွေပေးချေမှုအမျိုးအစား- T/T၊ L/C၊ D/PD/A၊ PayPal၊ ဘာသာစကား-အင်္ဂလိပ်၊ တရုတ်